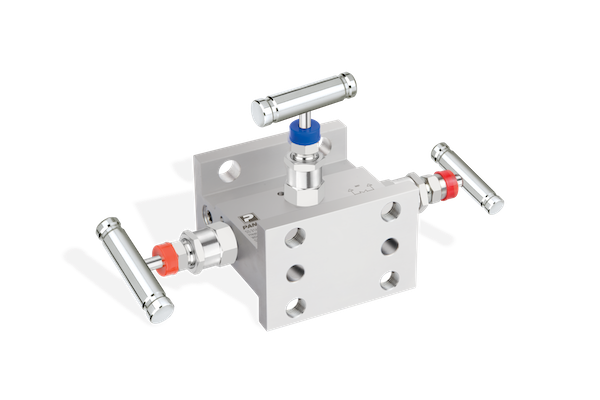

Two-valve Manifolds

PANAM Two Valve Manifolds are designed for connecting system impulse lines and transmitters. The two-valve configuration allows for easy isolation, calibration, and block & bleed for gauges, pressure switches, and static pressure transmitters. They are ruggedly manufactured, and precision machined to the exact dimensional tolerance to ensure perfect installation and application. These two valve manifolds combine the functions of a tee, a calibration valve, an isolation valve and all tubing and fittings into a single compact unit thus reducing the number of fittings and space required for installation. They are available in both A105 Carbon Steel and 316 Stainless Steel (Monel, Inconel and Alloy available upon request) and are rated for pressures as high as 6000 psi.

General product features:

- One-piece forged body without welds

- Safety bonnet lock

- Metal to metal seat

- Rolled and hard plated stem threads and tip stellated to prevent galling and extend life of valve

- Two-part stem tip arrangements

- Non-rotating ball tip to ensure bubble tight seal and shut-off

- Safety back seating on stem

- Standard PFTE packing, however GRAFOIL available for high temperatures upon request

- Maximum Working Pressure (MWP) and Temperature

- PTFE Packing: 6000 psi at 93°C and 4000 psi at 260°C

- GRAFOIL Packing: 6000 psi at 93°C and 3600 psi at 325°C

Quality test procedure:

- Nitrogen Gas at 1200 psi (80 bar) to ensure no leakage at seal and seat

- Hydrostatic test with pure water at 1.5 times maximum working pressure (MWP)

- Optional tests including Helium and Temperature available upon request